During this period, the crews performed the renovations

of the locker rooms, redid both the men’s and the women’s

bathrooms that serve the ballroom guests, installed new

kitchen ceilings and built a new room off the kitchen.

The bulk of the work took place in and around the

ballroom. “We had to completely gut and renovate their

ballroom and their pre-reception area,” said Garnant. “In

the ballroom, which is about 60 feet wide by 100 feet long,

our job was to abate the ceiling and put in a new one. We

also installed new structural steel because we bumped up

the ceiling heights.

“The walls go up 10 or 12 feet, and then the cove portion

merges into a much higher ceiling. The coved area was

in pretty bad shape—there were lots of wrinkles and it

didn’t look great. So one of our jobs was to go in there and

completely skim it down so it looked new,” he continued. “We

also had to repair 65 to 75 percent of the wood light covers

that they wanted to keep. We then put in new sprinklers and

new ductwork above, a new ceiling and new lighting.”

During this time, crews renovated an existing dining room

that had been closed off from the ballroom with old folding

doors. “We demolished the old doors, raised the bulkhead

and put in a new structural ceiling,” said Garnant. “We put

in new windows and doors onto an existing balcony that

overlooks the golf course. You have these big beautiful

windows that give you a much more expansive view.”

During the spring of 2015, one of the value-engineered

items that Woodmont Country Club added back in was the

replacement of the exterior terrace floor. “We ripped out

the existing floor down to the concrete deck, put in new

waterproofing and new tile from overseas to make a much

more open exterior dining area,” Garnant added.

EYE-CATCHING FEATURES

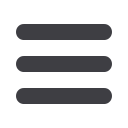

The transformation of Woodmont Country Club was

enhanced by the beautiful millwork throughout the

building. Potomac Architectural Millwork Corporation

installed approximately $1 million of millwork throughout

the country club, crafting 75,000 lineal feet—and 14

different types—of trim.

“Potomac actually moved their shop onto the site,” said

Garnant. “While they made some of the paneling at their

shop, they did all the finishing on site to make sure that

it fit just right.” The company used laser cutting tools to

make the precise shapes required for many of the wood

panels. “It was a tremendous effort. Other than the five

weeks when we did the ballroom and the pre-event area,

they did all the other millwork in about 3 ½ months. They

worked 10 hour days, six days a week and had as many as

25 craftsmen on the job at certain times.”

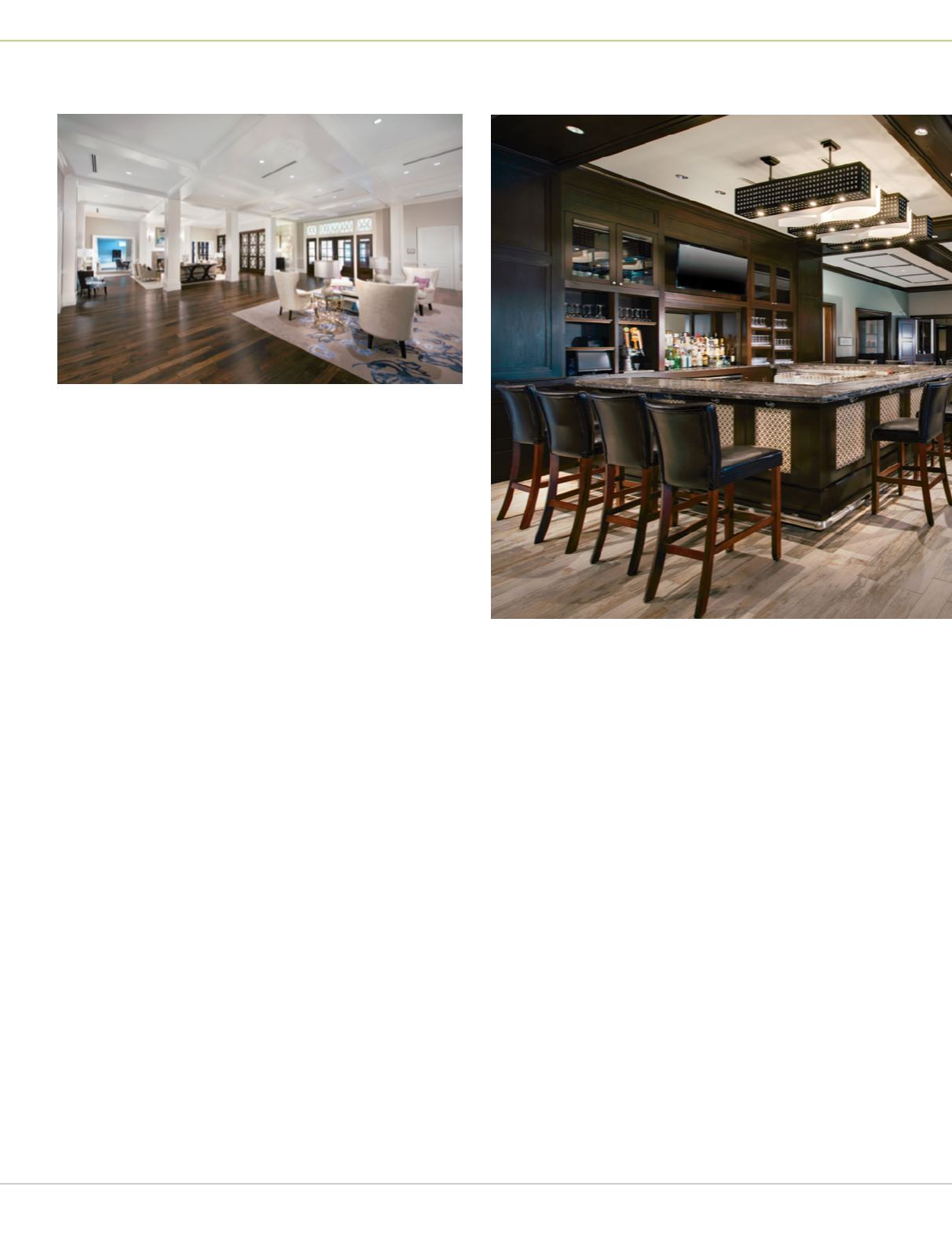

The main dining room includes the Trophy Room Bar

and one of the five new fireplaces in the country club.

CWC added the new club entrance, which features some

of the beautiful millwork created for the project.

8 Building Washington