WINTER 2014 | MARINE TECHNICIAN TODAY

21

1. Changing the compression ratio of the engine. Examples

of this would be head gasket thickness changes, milling

the cylinder heads, decking the engine block, modifying

the combustion chamber size or shape, and changing the

piston design.

2. Valve train modifications. Examples of this are camshaft

profile changes to vary valve lift and duration, intake and

exhaust valve enlargement, rocker arm ratio changes, and

valve spring variations.

3. Increasing air intake capacity. Examples of this are

changing or modifying the intake manifold, porting and

polishing of the heads or intake, modifying or replacing the

throttle body, changing the flame arrestor, and modifying

the exhaust manifolds or exhaust system.

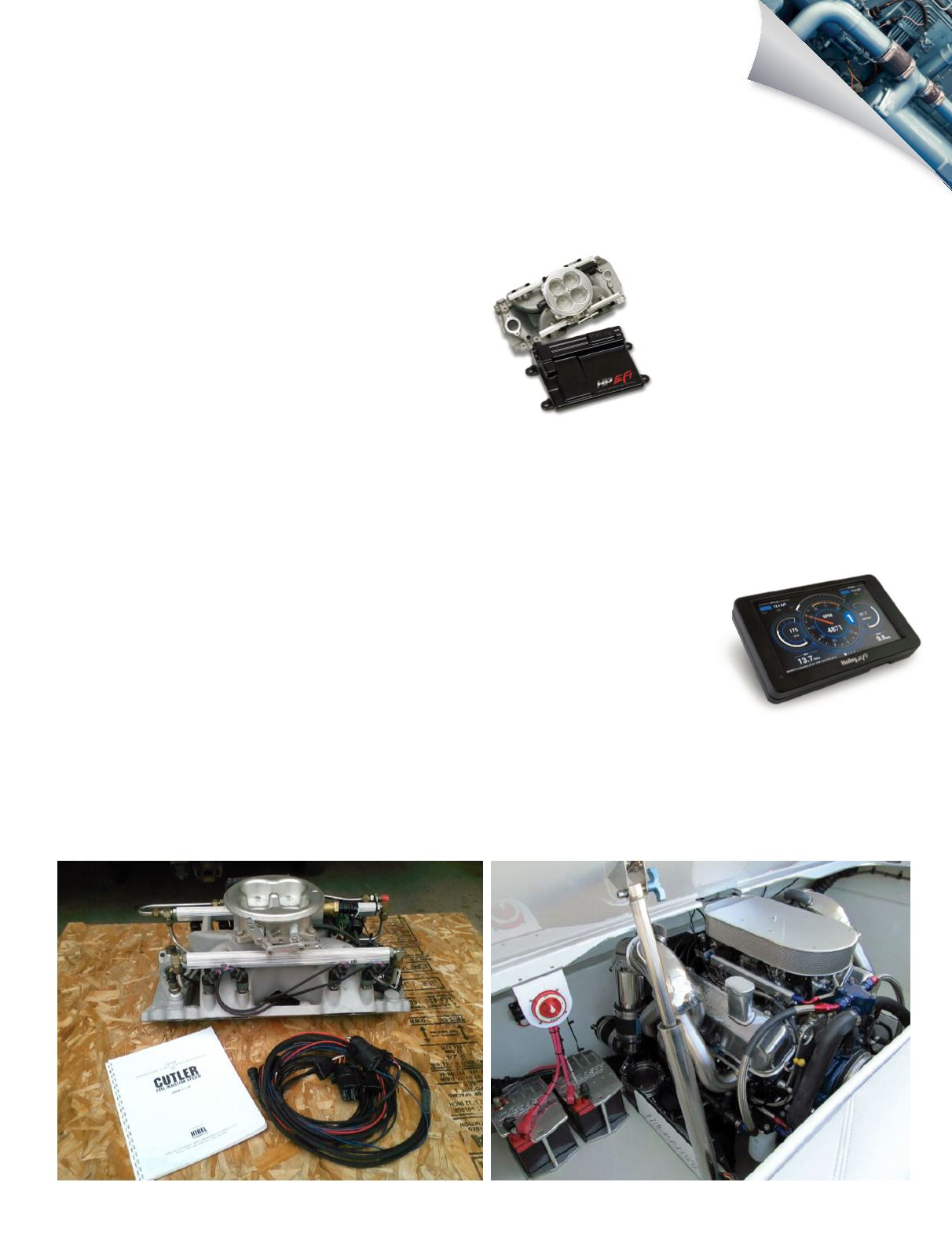

Often performance boaters desire to overcome the stock limitations of

their EFI system. The most popular engines these boaters wish to modify

are the MerCruiser 454 HO MAG at 385 HP, the 502 MAG at 415 HP, and

the 500 EFI and 525 EFI Mercury Racing engines. I contacted Bob Madara

of Marine Kinetics to get some modification advice. Bob’s background

starts as an engine development & engine builder in the Trans-Am

automotive racing series. In 2001 Bob redirected his efforts and started

his own business focusing on marine engine building and development.

Currently Bob is focusing his efforts in the development of marine engine

technology involving camshafts, valve trains, and induction systems. This

includes naturally aspirated and forced air induction systems. I specifically

asked Bob about exploring the performance potential of OEM EFI engines.

The most important mechanical parameter engines all have in common

is they are intake restricted when air flow demands exceed their design

limitations. Therefor the single most effective performance inhibitor is an

upstream intake air restriction. As performance boaters, when we move

forward on raising performance values, we are constantly defining the point

of the greatest restriction, mitigating that restriction and moving on to the

next greatest point of constraint. The common theme in the performance

development of this engine series is; there

are no downstream modifications (cylinder

heads, camshaft and valve train components) that will

compensate for an upstream air limitation. Let me clarify, a

properly sized, well developed cylinder head and camshaft combination

are the key to raising output, however they will only enhance performance

up to and not beyond the point of the intake limitations.

To demonstrate this point we can look at

Nascar racing. When they need to reduce

horsepower because of safety concerns

they require the installation of a restrictor

plate. By reducing the airflow into the

engine they can drastically reduce the

horsepower created. Even the incredibly

talented engineers of Nascar understand

that their only compensation is in

efficiency. That’s exactly what’s required in the modification of any intake

restricted engine. You can increase finite measurable gains downstream

of the intake by optimizing exhaust, compression ratio, cam profile etc.

However, once you have exceeded the limitations of the intake manifold,

this becomes the liming factor in your power output.

The engines offered by the OEM’s

need to be a compromise between

performance, durability, and price.

These compromises usually are not to

the benefit of the performance boater. To

improve performance you first you have

to increase the airflow into the engine

and improve the hard parts of the engine

such as changes to the camshaft, valves,

pistons, etc. The second challenge to enhance the engines performance

potential is the electronic engine management systems. Ultimately, the

success or failure of our project will fall on our abilities to tune & calibrate

the engine. Regardless of how well we have addressed the design of

the hard parts in the system, without the correct tune and calibrations