16

MARINE TECHNICIAN TODAY

|

WINTER 2014

VOLATILITY

How easily does the oil vaporize or boil off?When oils are hot, vaporization

can result in significant oil consumption and thickening of the oil. Not only

is this a problem for oil consumption, but the oil vapor is sucked into

the engine via the Positive Crankcase Ventilation system, contributing to

significant hydrocarbons in the exhaust (PCV systems have been used

in gasoline engines and are now starting to be used in diesel engines).

In petroleum oils, the molecular structure is non-uniform, consisting of

various size compounds. Imagine countless footballs, baseballs, hockey

sticks and tennis rackets all mixed together, pushing against each other.

When the oil gets hot, some of the lightweight items are liberated and fly

away while the larger, heavier items remain. As this process continues,

only the larger items remain, resulting in much thicker oil. In contrast, the

molecular structure of synthetics is like a bunch of identical golf balls, all

the same size and tightly packed together, resisting vaporization; as a result,

they stay in grade for much longer periods and reduce oil consumption.

Volatility Advantage:

Strong for Synthetics

SEALS

How does the oil affect the seals? Will it cause them to shrink or to swell?

And, is the oil chemically compatible with them? Seals aremade of a variety

of compounds in order to provide rigid but flexible surfaces that promote

good sealing in order to keep liquids in and dirt out. Petroleum oils are fully

compatible with the seal materials used in modern engines and will slightly

swell the seals. While PAO synthetics tend to shrink seals, Esters tend to

swell the seals: both are chemically compatible. In synthetics where PAO

is the primary base oil, another synthetic oil, Diester for example, is used

to provide the desired seal swell and nourishment for seals. Historically,

seal compatibility issues have caused real and imaginary problems for

synthetic oils in the market place. Currently, seal issues for properly

blended synthetic oils are no longer an issue.

Seals Advantage:

Slight for Petroleum

LUBRICATION/WEAR PROTECTION

How well does the oil lubricate and, in turn, prevent wear? Lubrication

is a result of both base oil and additive combinations performing in various

lubrication regimes in order to prevent metal-to-metal contact and the wear

that results. Where fluid film is retained, the base oil will be the dominant

factor in lubrication. Where oil film is not always able to separate the

moving metal parts, additives become the dominant factor. The uniform

molecular structure of synthetics results in a superior lubricating film.

Additionally, the thermal stability of synthetic oils maintains an oil film

in much more severe conditions – at higher temperatures, for instance

– than petroleum. Additives are relatively equal in performance regardless

of the base oil – synthetic or petroleum – with which they are combined.

Instead, the anti-wear protection they provide – or fail to provide – is

more dependent on their own quality and concentration. For normal

temperatures, properly additized petroleum oils and synthetic oils will

show similar lubricating qualities. Synthetic oils have higher film strengths

and require a lower quantity of additives in order to achieve the same level

of protection. In standard anti-wear testing such as the Shell four-ball wear

test, some synthetics achieve up to four times the wear protection when

compared to petroleum oils. When higher temperatures and pressures are

used in such tests, the results significantly favor synthetic oils.

Normal Operational Conditions Advantage:

Slightly Synthetics

Severe Operational Conditions Advantage:

Very Strongly Synthetics

OIL LIFE / ENDURANCE

How long can the oil provide proper lubrication and perform all required

functions? Oil life is a function of time and severity of service and can vary

from application to application. Oil is said to be condemned, that is, not fit

for continued service, when one or more of the following conditions exist:

• Viscosity has decreased by one grade or increased

by more than one grade

• Fuel contamination is greater than three percent

• Soot level exceeds four percent

• Total dissolved solids are greater than four percent

• Total Base Number is less than two percent

• Critical additives are depleted

• Oxidation number greater than 50 (30 for petroleum)

• Nitration number greater than 50 (30 for petroleum)

As explained above, synthetic oils are less likely to thicken as the result

of vaporization or oxidation and they stay in proper viscosity grade for

significantly longer periods of service. Several of the other factors for

condemnation are the same for either synthetic or petroleum oils and are

more dependent on the quality and concentration of chemical additives

required to continue to provide service. Soot and total dissolved solids

are products of engine combustion and are proportional to fuel air

management; turbo charged engines tend to burn cleaner than naturally

aspirated engines. Filtration, especially bypass filtration, will have direct

effects on soot and dissolved particles and can be effective at increasing

oil life. Since lubricating oils are products of base oils mixed with chemical

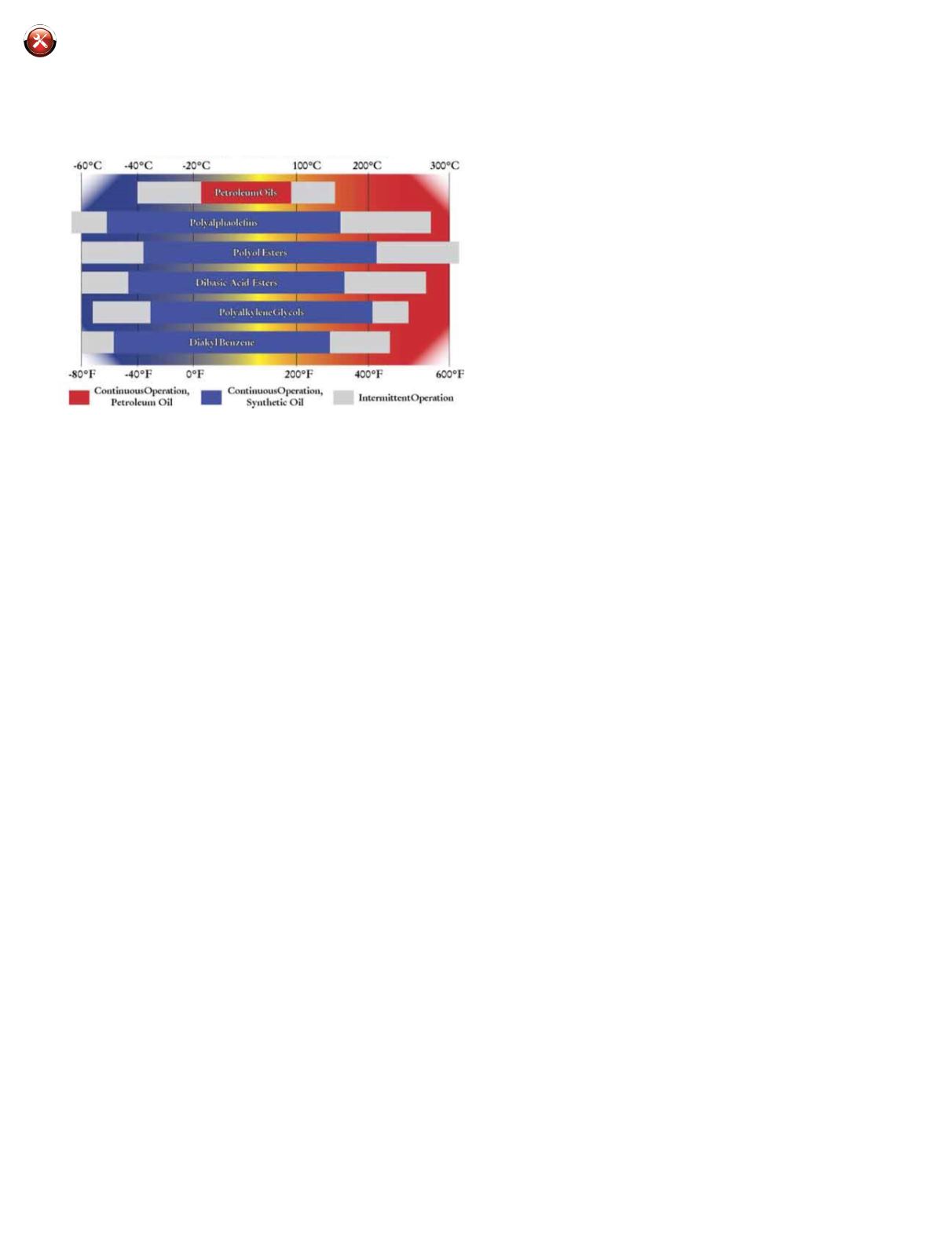

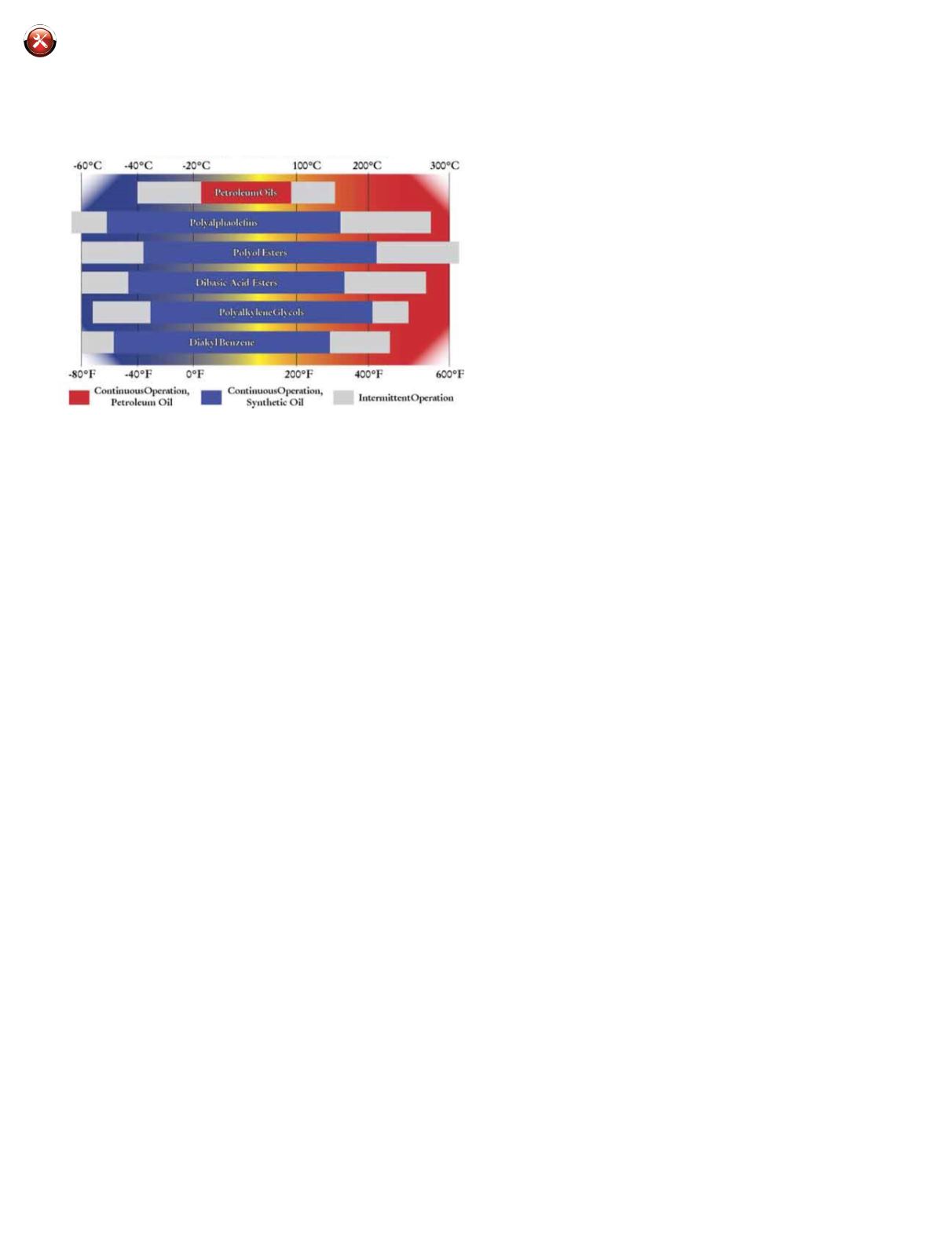

CHART TWO: OIL TEMPERATURE LIMITS

PETROLEUM VERSUS SYNTHETIC

,

TECH TALK