feet thick and reinforced not only with the typical mild steel

reinforcement but also with structural steel wide flanges

—14-inch beams and steel plates up to 2.5 inches thick.

“Again, we had to understand how excavation was going to

proceed so we could really calculate the stresses in the slab

in every condition, and the contractor had to understand

how the system worked so they could plan their excavation

sequences around that. It was really a lot of back and forth; we

had some say in construction, and the contractors had some

say in the design, to a much greater extent than what you

would have in any other building,” said Crilly.

Since many of these design decisions were made early in the

project, while there were still many unknowns, the project

team had to constantly review the design to make sure that it

would still work with the actual construction sequence.

WEATHER CHALLENGES

Below-ground construction was completed by February 2013

and, by that time, the above-ground construction had reached

the building’s eighth level. Since work had fallen behind

schedule, Hensel Phelps asked Miller & Long Co., Inc., which

was building the conventionally reinforced concrete frame

above ground, to work double shifts.

“We achieved substantial completion of the concrete frame in

the first part of June 2013, which was in accordance with our

original schedule developed in 2009,” said Carlat.

“And then the rains hit. The summer of 2013 was the fourth

wettest on record in DC, and we had a building with a large

opening in the center where the glass skylight was going into

the roof. We were taking on a tremendous amount of water,

because the building acted like a funnel; water went to the

lowest level, and to get to the lowest level, it had to go through

a lot of high-finish areas like the ballrooms and meeting

rooms. We were well into interior construction all the way up

to the eighth floor when this was occurring,” said Carlat. “There

were a lot of provisions in place—barriers and tents to control

the water—but when you’re taking on three inches of water a

day, those systems were not adequate to handle the incoming

water; they had been geared towards normal rains.”

Mitigating that problem, which included removing and

replacing some drywall, required Hensel Phelps and its sub-

contractors to regroup once more to maintain the schedule.

The glass roof was finally placed in late November 2013,

and crews made a final push during the first four months of

2014 to complete the job. “We always knew that would be a

challenge; there was no other way to do it other than to make

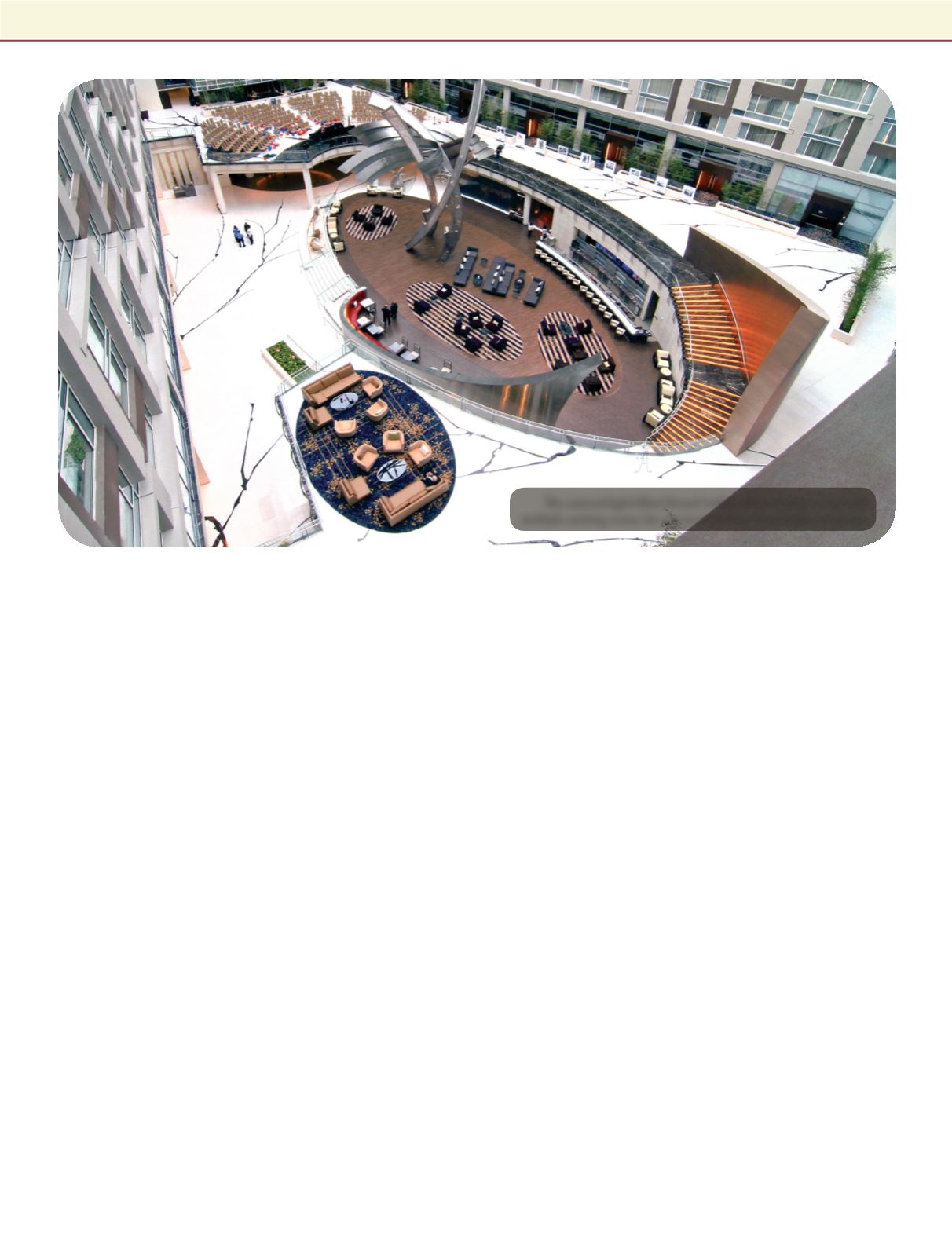

The natural-light-filled Grand Lobby offers visitors a bar and

multiple seating areas for conversations or impromptu meetings.

12 Building Washington