24

MARINE TECHNICIAN TODAY

|

FALL 2014

The ECM takes this information from

the MAP sensor and increases the injector

pulse width (the injector stays open longer), therefore

increasing the amount of fuel delivered to the engine. When the

throttle is pulled back, the opposite happens. The ECM controls fuel

management, ignition timing and onboard diagnostics. It continuously

monitors and adjusts these systems. Other sensors such as IAT (intake

air temperature), ECT (engine coolant temperature), and others refine the

fuel delivery of the injector. The ECM has a diagnostic feature that records

engine hours and trouble fault codes.

Having anunderstandingof the basic operationof theMEFI engineswill help

with diagnostic testing, and it will aid in making the correct decisions about

performance upgrades. The high performance segment of the industry has

found that increasing the horsepower on an EFI engine is more difficult

than on an older carbureted engine. On a carbureted engine, changes to

the compression ratio, ignition timing, exhaust, heads, intake manifold,

and camshaft would show and increase in horsepower and torque. The

increased airflow through the engine resulted in more air being pulled and

fuel being delivered through the carburetor. Not so with an EFI engine. The

airflow increases, but not the fuel flow. The fuel flow is still regulated by

the ECM, and it has no way to identify that any modifications have been

made. To gain any performance due to engine modifications will require

changing tuning in the ECM by reprogramming it. There simply is no stock

external means of increasing fuel volume, fuel pressure, or advancing

timing manually. Remember the only way to make more horsepower, no

matter if the engine is carbureted or EFI, is to increase air flow and fuel flow

into the engine in a precise manner. This will keep the stoichiometric ratio

correct throughout the rpm range.

One misconception of EFI engines is that they are self-adjusting. In reality it

is to a point only if the engine is completely stock. The ECM is programmed

for engine size, camshaft type, compression ratio, horsepower output,

idle quality and many more parameters within the engine. Once the base

program is established, compensation parameters for altitude, ambient

temperature, knock and various outputs are programmed into the ECM.

The compensation parameters can only operate within a few percentage

numbers of the base program. If the input signals to the ECM are not within

its programmed parameters, the output for the fuel, spark and timing will

not be correct. It is now easy to see that engine modifications can cause

the engine to run poorly, not stay running, or not start at all. Many times

it will compromise the engine’s fuel economy, reliability and drivability. It

may cause pre-ignition and detonation and ruin a perfectly good engine.

It can take many hours of dynamometer work to develop the proper re-

mapping of the stock ECM.

I have seen boat owners spend thousands of dollars on performance

upgrades to their EFI engine and not gain one ounce of speed. They don’t

have the ability to correctly re-map the ECM and verify proper combustion

.

MEFI 3 ECM

.

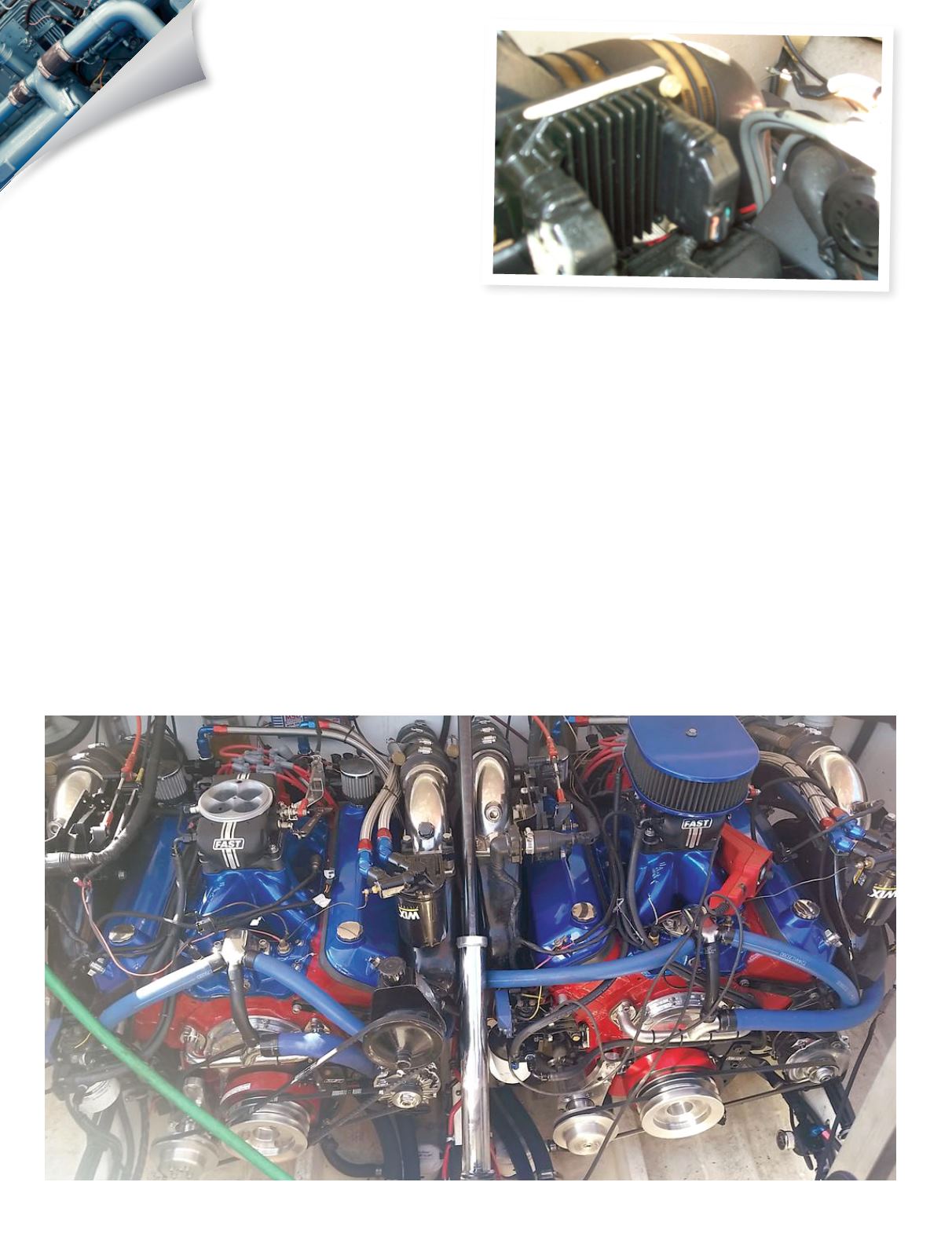

FAST Marine EFI install